mPower™ DC Autoranging Power Supplies

What is an Autoranging

Power Supply? ↑

- Allows the delivery of the full power rating across a wider range of voltages and currents.

- Enables one moderately sized power supply to replace multiple small ones, or one very large one.

- Saves capital costs, rack space, and simplifies test setups.

Autoranging is a power supply design feature used in test applications which maintains peak power delivery (watts) across a wider range of voltage and current test points compared to traditional power supplies. This is accomplished by designing the system components to operate at higher voltage with low current, and higher current with low voltage, but at a lower maximum power load. This allows a single, smaller power capacity power supply to serve a wide range of test cases which would otherwise require multiple traditional power supplies. This saves capital costs, rack space, and even simplifies test setups.

To visualize what autoranging does, imagine a test case where the DUT must work at a full 3.0 kW across a range of voltages. To sustain 3.0 kW, the range of test voltages will require a range of current capacity. A dc power supply typically delivers its full power at only one peak voltage and current combination. As shown in the bottom graphs, it may take several traditional 3 kW supplies with limited ranges, or one excessively large one to deliver 3.0 kW at various voltages.

In the top graph, we see that Marway’s mPower, a 3 kW autoranging power supply, offers a much broader voltage and current range than the traditional 3 kW power supplies. This example power supply delivers 3 kW along the entire thick blue line. For the 3.0 kW test case, a single, modest power supply can be used. mPower comes in six power sizes from 1.5 kW up to 30 kW per unit.

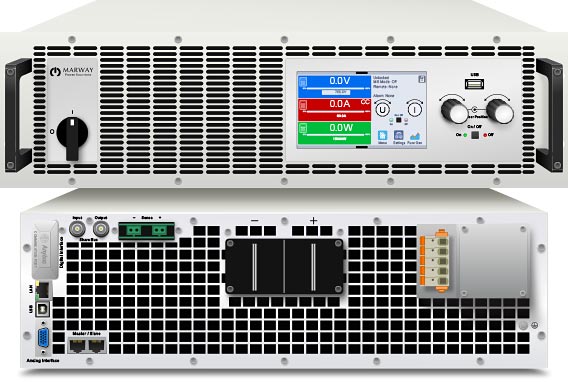

411 Series Autoranging,

Regenerative, Bidirectional

DC Power Supply ↑

The 411 Series provides full power source and sink functionality with the ability to return energy to the grid at up to 96% efficiency.

The advanced control system includes autoranging for wider voltage and current test points, a rich function generator, menu-driven touchscreen operation, and numerous options for remote control over Ethernet, USB, and even analog.

With up to 30 kW per unit, and 64 units in parallel, the 411 series is ready for the challenges of large capacity renewal energy and vehicle electrification development, as well as inline production testing. The advanced capabilities of the 411 are also available in packages as small as 3.0 and 1.5 kW meaning it’s a productive choice for applications of nearly all sizes.

The 411 and 311 Series are essentially identical, except that the 411 is bidirectional (source and sink), and the 311 is unidirectional (source only).

311 Series Autoranging, Programmable DC Power Supply ↑

A 311 Series autoranging power supply provides a wider range of voltage and current capacity for it’s given power rating than conventional power supplies. This allows for more test options from a single unit saving both space and cost.

The advanced control system adds a rich function generator, menu-driven touchscreen operation, and numerous options for remote control over Ethernet, USB, and even analog.

With up to 30 kW per unit, and 64 units in parallel, the 311 series is ready for the challenges of some pretty large capacity applications. The advanced capabilities of the 311 are also available in packages as small as 3.0 and 1.5 kW meaning it’s a productive choice for applications of nearly all sizes.

The 411 and 311 Series are essentially identical, except that the 411 is bidirectional (source and sink), and the 311 is unidirectional (source only).

300 Series Autoranging, Programmable DC Power Supply↑

The 300 Series dc power supply line packs a lot of advanced features into a cost-effective, small package.

Like the 311 and 411, the 300 Series is an autoranging power supply allowimng for a broader range of voltage and current setpoints for it’s given power rating than conventional power supplies. This allows for much greater test options out of single unit.

The system can operate in constant voltage, constant current, or constant power, automatically transitioning between each. The graphical display shows actual DC output values, the limit setpoints, and status. The display is also used to for navigation of the on-board menu of system settings.

The system can be remotely controlled over Ethernet or USB, and has an alaog control interface as well.