Optima™ Custom PDUs

Product SelectorCustom PDU Advantages ↑

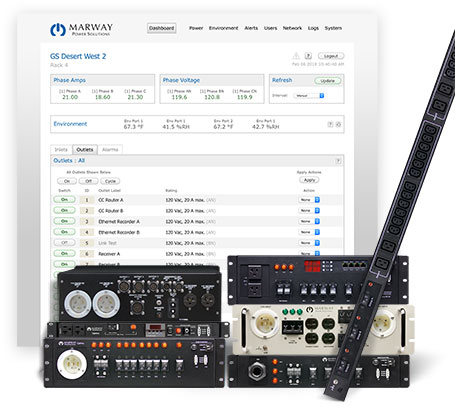

A custom PDU is a power distribution unit designed to consolidate power management needs such as electrical noise filtering, power monitoring, outlet control, safety interlocks, and more into a single-enclosure solution tailored to your application.

The best custom PDUs take into consideration the physical environment, electrical environment, and operator environment. Marway specializes in working closely with customers to customize solutions which balance all requirements and considerations.

Overcome limitations of standard products

- Customization options to meet your application’s exact needs.

- Achieve perfect control with custom branches, switching, metering, and more.

- Simplify installation by using the exact connectors needed.

- Integrate safety systems with EPO and other interlocks.

- Get the exact size and shape enclosure needed.

- Up to 400 amps, 480 volts, AC or DC, 50/60 and 400 Hz.

- Standard operating environment of 32° to 122°F, 5% to 85% R.H., up to 6,562 feet (0° to 50°C, 2,000 m.). Extended ranges are possible.

Protect equipment against noisy power

- Meet EMI standards using filters and shielded enclosures.

- Mitigate voltage spikes/transients using surge suppression.

Save space with power source consolidation

- Consolidate ac and dc sources into one distribution system.

- Create step up or down voltages with internal conversions.

- Create dc from ac, or ac from dc within a single unit.

Take advantage of a team of experts

- Reduce overall design time by using the expertise of a specialized design and manufacturing team.

- Be assured components are properly matched for efficiency, signal quality, and reliability.

- Let Marway manage compliance testing and certification to meet regulatory needs.

Custom Power Conditioning ↑

to protect against noisy power

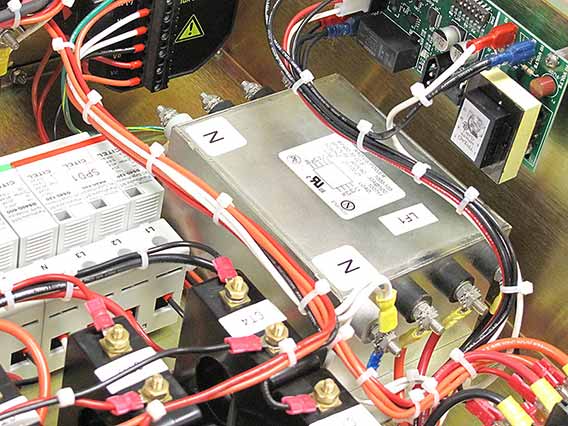

Since many signal problems are introduced to power lines through a facility’s own wiring, adding power conditioning at points throughout the facility is beneficial. An effective place to do this is in a PDU right before the application equipment. A custom PDU can incorporate solutions specific to your application.

- Protect equipment from spikes with correctly-sized surge suppressors.

- Mitigate inducted and conducted EMI with application-matched filters and isolation transformers.

- Minimize radiated EMI with shielding and other techniques.

- Address application-specific needs by optimizing the selection of components for capacity matching, packaging efficiency, and cost.

Custom Power Configuration ↑

to combine or generate ac and dc sources

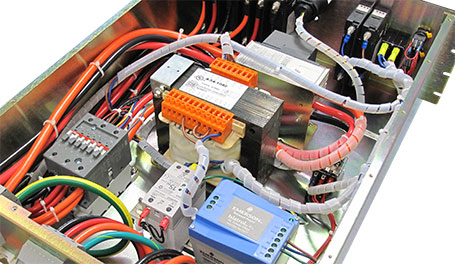

Marway specializes in the single-chassis integration of different power forms. Consolidate what often requires multiple separate units into single enclosure to lower costs, save space, and reduce installation overhead. Multiple options cover several power forms and conversions.

- Up to 480 Vac, 400 Vdc, and 400 Amps.

- 1Φ, 2Φ (split phase), 3Φ delta and wye.

- Conversion of source voltage (step up, step down).

- DC to DC conversion to change voltage or create isolation

- Voltage isolation.

- Customized overcurrent protection and circuit branching.

- Multiple inlet sources for variety or redundancy.

Custom Connections ↑

for distribution, switching, and interlocks

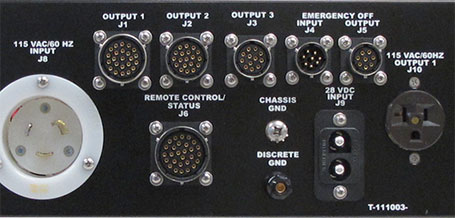

Not everything has a NEMA 5-15 plug. We get that. Since we design our own custom PDU enclosures, we can accomodate your choice of any common or specialized connector in any combination needed.

- NEMA, IEC, straight blade and twist lock outlet options.

- Pin and sleeve, circular/MIL, marine connectors.

- Multi-pin signal connectors.

- High-current lugs and even screw terminals.

Custom Controls ↑

to control and monitor unique needs

Most custom PDU options end with outlet choices. When your application is unique, you also need the freedom to configure custom control and monitoring systems. We can tailor distribution circuits, control signals, monitoring sensors, and more so your application can do the job it needs to.

- Multiple individually breakered circuits.

- Power quality meters, power usage displays.

- Manually switched, and remotely switched outlets.

- Integrated EPO, remote interlocks.

- Ethernet switching and power monitoring.

Custom Form Factor ↑

to build the perfect all-in-one

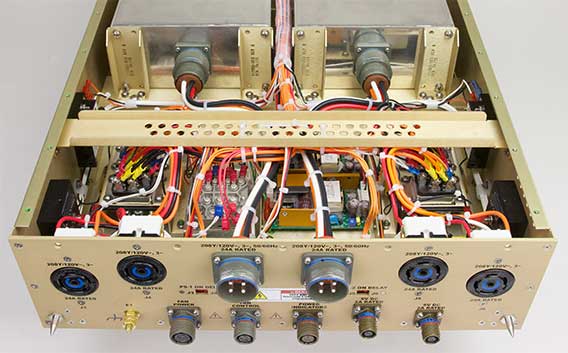

Not all needs fit into a 1U or 3U enclosure. Not all distribution enclosures are rack mounted. In addition to standard rackmount solutions, Marway has created custom power distribution units in uniquely-sized and shaped enclosures up to full-sized racks.

A custom enclosure enables consolidation such as integrating an isolation transformer, a power supply, or other equipment. Consolidation can reduce space, weight, and costs by eliminating redundancies. It can even save on installation time and reduce the overhead of managing multiple SKUs.

- Traditional horizontal rack pdus in sizes 1U and larger.

- Vertical 0U enclosures for back-of-rack installations.

- Non-rack enclosures from small OEM power modules to large cabinets mounted into custom framing systems.

- Consolidate features of multiple similar custom PDUs to improve configuration management and reduce inventory.

- Enclosures specialized for military applications, industrial applications, and commercial applications

Networked and Non-Networked ↑

Connectivity is becoming an increasingly more common requirement even in traditionally non-connected environments. Marway offers Ethernet-based switching and power monitoring in addition to traditional control methods in both it’s standard products and custom PDU products.

- Non-networked PDUs are still the backbone of power distribution when only local control is needed.

- Non-networked PDUs can still incorporate remote control for outlet switching, EPO, interlocks, and other discrete signal needs from nearby panels.

- Marway’s RCM technology provides inlet power monitoring, outlet switching over HTTP/S, SSH, Telnet, RESTful API, and SNMP.

That Special One, or

Those Special Hundreds ↑

Marway’s design and manufacturing processes have served customers needing a single, highly-customized PDU, to customers needing repeatable orders of hundreds of units. Whether you need that one specialized feature or chassis design that no one else offers, or you need a fully-collaborative design project to optimize a complex set of PDU options, Marway can help. Likewise, when it comes to meeting production demand, Marway can create that one unit no one else will, or deliver hundreds of units to meet your production planning needs.