Military Power Distribution Units

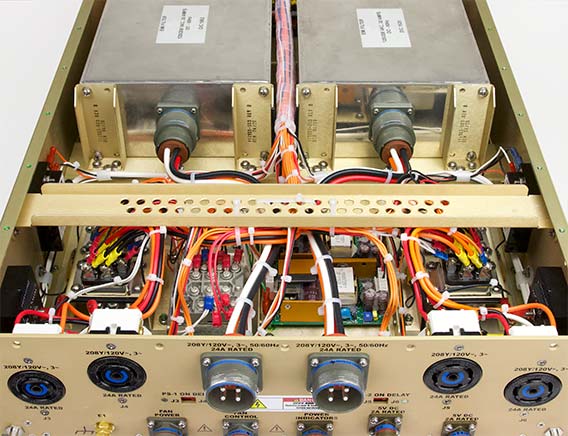

BACN

Airframe Comms Node

Multiple PDUs aboard an E-11 jet support the BACN communications payload. These PDUs support an array of equipment used aboard the E-11 to connect disparate tactical systems used in the battlefield while meeting EMI, thermal, and vibration requirements.

AMDR

Missile Defense Radar

Marway supported this design program for several years as changes evolved during AMDR development. Includes a number of custom control features to support connected computing equipment. Testing and analysis to several 810 and EMC standards.

NGATS

Field Test & Support

This unit distributes and monitors power in multiple power forms for a variety of application and computing equipment. Power data is communicated over Ethernet. Designed and tested to various sections of 810, 167, 1399, and MIL-HDBK-217 standards.

VPM

Virginia Payload Module

Supporting submarine weapons systems, this PDU consolidates conversion, conditioning, auto transfer, and distribution from sprawled out panels. Integrated test points and blind-mate connectors further simplified installation and support.

Turret Radar

Munson Road Testing

Several PDUs power a turret radar system undergoing testing at the Munson test area. The PDUs provide AC and DC power to motors and peripheral controls, and include remote switching outlet control. The test platform rides in an RMMV vehicle.

CIGTF

InFlight Test Lab

Marway modernized the payload power distribution aboard the 746 Test Squadron's C-12 lab. Powering test equipment for navigation and guidance systems, the PDU converts up to 400A of 28 Vdc into AC power while meeting shock and vibration requirements.

Meeting Military Power Challenges

Military PDUs often differ from commercial PDUs in some obvious and not so obvious ways. Obvious, is that certain battlefield applications do indeed require extraordinary tolerance of shock, vibration, and weather extremes. Not so obvious, is the need to condition incoming raw power to deliver clean, stable power to mission critical electronics. There are a lot of unique control and connectivity needs in military applications as well.

Marway has been meeting the needs for military PDUs in ships, submarines, planes, forward command bases, hardware service bays, and even as support for research and product development for over 30 years.

What to look for in a military PDU ↑

- Protects downstream equipment from noisy facility power using EMI filters, surge suppressors, and other techniques.

- Saves space by integrating conditioning and conversion needs instead of housing them as external boxes.

- Improves integration by providing the exact connectivity and controls needed for site-specific equipment.

- Complies with general and military-specific standards for electrical power handling equipment.

- Meets harsh environmental needs.

What to look for in a PDU supplier ↑

- Takes the time to understand the application, explore needs, and consider design options.

- Optimizes the selection of application-specific components for capacity matching, packaging efficiency, and cost.

- Designs and manufactures enclosures to meet unique needs for installation, cable routing, and other integration details.

- Manages the entire process of standards testing and certification, when required, prior to delivery.

- Understands military platforms and applications, and can apply specific military standards to PDU design.

Programs, Platforms, and Applications ↑

- Aircraft, naval surface vessels, submarines, UAV, ground vehicles, and others.

- Development test roles, simulation, support facilities, and forward operating bases powering mobile data processing to multi-rack test and service bays.

- CSRR, AMDR, VPM, BACN, WIN-T, and other programs.

- Supporting communications, weapons, intelligence, and research systems.

Compliance and Standards ↑

- Certified AS9100 with ISO 9001.

- TAA, ITAR, and NIST compliant.

- General MIL-STDs 461, 810, 901, 167, and others.

- Platform-specific MIL-STDs 1399, 704, and 1275.

- Environment and reliability testing/certification when required.

- UL and CE certification (others when required).

Custom, COTS, COTS-Modified ↑

- Marway specializes in application-specific PDUs.

- Rackmount chassis from 0U to 24U, to rack sized.

- Custom enclosures for non-rack applications.

- Ac, dc, 400 Hz — up to 600 volts, 400 amps.

- We have nearly 300 standard basic and smart PDUs.

- 1-phase, 3-phase, 15-, 20-, and 30-amp models.

- 1U, 2U, 3U, and vertical 0U configurations.

Conversion, Conditioning, and Control ↑

- Meet EMI standards using filters and shielded enclosures.

- Mitigate voltage spikes/transients using surge suppression.

- Integration of ac and dc sources.

- Conversions for ac-ac, ac-dc, dc-dc, and dc-ac.

- Local and remote power monitoring and switching.

- Individually breakered branches.

- EPO and interlock integration and remote panels.

Networked and Non-networked ↑

- Non-networked PDUs still offer some remote switching through discrete signals from remote panels.

- Networked PDUs offer remote control and monitoring over Ethernet using HTTP/S, SSH, Telnet, and SNMP.

- Remote switching of outlets.

- Remote monitoring of inlet current, voltage, and power.

- Event alerts for startup, user login, outlet state change, EPO, current and voltage setpoint excursion, and configuration changes (via SNMP, email, SMS).

- Scripted automation through Telnet, SSH, SNMP, or RESTful API over HTTP/S.

What is a Military PDU? ↑

A military PDU is an electrical power distribution unit designed to meet the needs for stable power and unique integration into military environments. For some applications this can mean operating in punishing environments of vibration, shock, dirt, extreme weather, etc. However, many applications operate in more ordinary industrial-like environments, but with military-specific needs for controls, connections, and enclosures. Compared to commercial products, military PDUs often include features to clean up signal problems seen with noisy power sources, and include power forms, controls, and safety features not common in commercial PDUs.

Key Capabilities of Military PDUs

- Optionally built to MIL-STD 461, 901, 810 and other standards to handle harsh conditions such as vibration, shock, and environmental extremes.

- Reduces or eliminates conducted and inducted electro-magnetic interference (EMI) from nearby electrical equipment.

- Protects against voltage spikes created by high-powered equipment on the same lines, and lightening strikes near outside transmission lines.

- Integrates remote interlocks to cut power to outlets to meet military safety requirements.

- Creates multiple power forms from a single facility power source such as higher or lower voltages, or even dc power from ac power and vice versa.

- Adopts the use of specialized connectors and outlets to interface to existing customer equipment, safety systems, and more.

Battling Noisy Power ↑

Noisy source power signals occur in military environments due to the varying loads of nearby high-powered equipment. Similar to how sudden water pressure surges cause pipes to rattle, sudden surges of “pressure” and “flow” (voltage and current) in electrical lines cause disturbances in power signals. Where a weak fitting along a pipe might leak, a vulnerable component in an electronic system may fail.

Most COTS PDUs are designed for office-like or data-center environments where there is little influence on power signals from nearby equipment. At most, these PDUs may have some surge protection, since those devices are relatively low cost and small.

Military PDUs will typically need to integrate surge suppression, EMI filters, isolation transformers, and other tools to mitigate the severity of noisy power signals caused from many different sources. This can be especially true for electrically isolated environments like ships, planes, and other mobile platforms where significant equipment exists on the same power subsystem. Selecting these components requires an understanding of the types of noise which are expected in the environment, and matching various attributes of the components to the power form being conditioned.

Integrating Needed Power Forms ↑

Many military environments need a mixture of different power forms. A power form is the combination of specifications for voltage type, voltage rating, and current rating. For example, 220 Vac, 15 amps vs. 80 Vdc 60 amps are two different power forms.

A building or mobile platform will usually have a master power source which may be transformed into a couple of different forms for facility distribution. In many environments, this is typically three-phase ac power for some areas in addition to common 120 volt wall outlets. In military applications, where there’s a diverse range of equipment, there may be a need for more types of power. Ac may be needed in multiple three-phase and single-phase forms. Different voltages may be needed to serve the larger and smaller pieces of equipment. Even dc power is often needed in various voltages in the same work spaces as ac power.

The PDU which will already be needed for distribution, is a convenient and efficient place to integrate transformers, power supplies, and power converters to create multiple power forms from a single facility or generated source. This can simplify installation, and provide better control options compared to having multiple power services wired throughout a facility.

Meeting Unique Control and Connection Needs ↑

Military PDUs often require a wider range of circuit designs, control features, power monitoring, and even remote management capabilities. Most commodity power distribution products have a single circuit serving all outlets with perhaps an on/off switch or breaker. Military environments often require more control over multiple individual circuits. For many applications, digital power displays are important. Indicators for the status of specific circuits and interlocks are simple additions, but unique to each application. Adapting to these unique switching, display, and control needs, is a key need in a military PDU.

Another area of important flexibility for a military PDU is that of cable connectors. Most PDUs are designed for only the common wall sockets in offices and homes. In the military realm, there are numerous specialized connectors. While there are standardized ac power connectors, even they come in dozens of types depending on voltage, current, safety features like locking, resistance to water, vibration, and more. Even more than power connectors, control signal connectors are even more varied. Integration to external interlocks, sensors, and more require that a PDU have the flexibility to incorporate what a facility needs.

Standardized industrial PDUs which might work in some military applications, like Marway’s 5 and 8 Series, will be designed with common connections and controls, but ultimately, many military PDUs need a custom design to meet their needs.

Handling Harsh Environments ↑

A consideration for some military power distribution applications is the environment the PDU will be used in. Military, of course, conjures images of the battlefield. While not all military PDU applications are in front-and-center war fighting hardware, there are some, and there are plenty of forward operating bases which also have similar demanding needs. Enclosures, connectors, and controls may need to handle dust, rain, and even the build up of ice. Even indoor systems may be subjected to significant dust and/or the potential for water splashing.

At the extreme, vibration and shock may be a consideration. PDUs mounted to mobile platforms need to handle vibrations and possible jarrings experienced on the road, in the air, or even at sea. And in those applications where the PDU is in the battlefield, meeting the requirements of MIL STD 901D is a critical capability.

Whether outdoors or indoors, temperature can be an extreme environment factor. To handle cold environments, specialized components, or even internal heating, may be necessary. Depending on the use of electronic controls in the PDU, cooling by convection venting or fans may also be an issue for very warm environments.

Since most pre-designed, standard PDUs are going to be designed for general purpose applications, they’re not likely to meet many harsh environment needs. Most harsh environment applications tend to be unique in their power needs anyway, so custom designs are often used. Marway specializes in custom PDU applications, and is experienced with a number of the skills and standards used to handle harsh environments.