Optima™ Custom PDUs

Product SelectorConversion ↑

Many installations of electronic equipment require more than one type of power source. There can be advantages to consolidating multiple power sources and adding power conversion into a single PDU. Using transformers (ac), power supplies (ac to dc), converters (dc to dc), and inverters (dc to ac) we can optimize space, weight, cost, and even simplify the installation and operation.

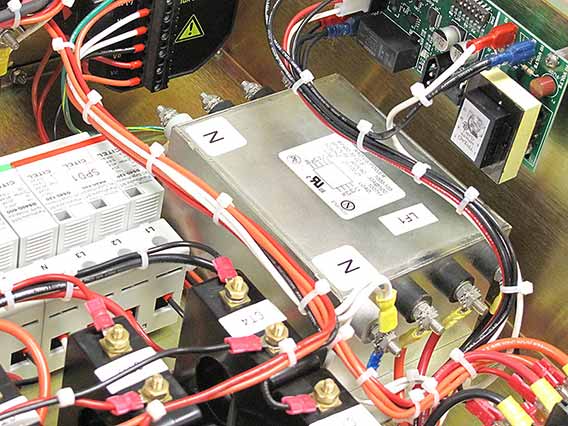

Conditioning ↑

Facilities have imperfections in their power signals which can cause poor performance, incorrect functionality, or even damage. Most equipment has limited built-in protection against this. There’s a basic assumption that incoming power is clean. Marway can consolidate power conditioning into the PDU using EMI filters, transformers, varistors, and other features to assure a clean and stable power signal.

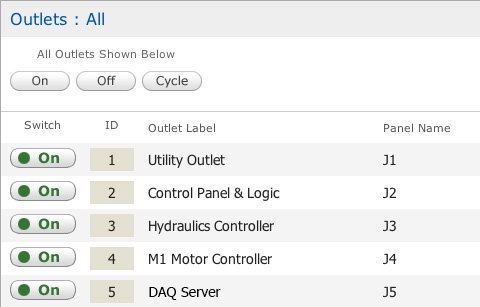

Control ↑

Safety considerations of power control include over-current protection and easy access to power shutdown for emergency conditions. Safety aside, most controls are added to PDUs for operator convenience. Circuits and outlets can have on/off control through local breakers, switches, or relays, through remote panel switches, or even through software over an Ethernet network.

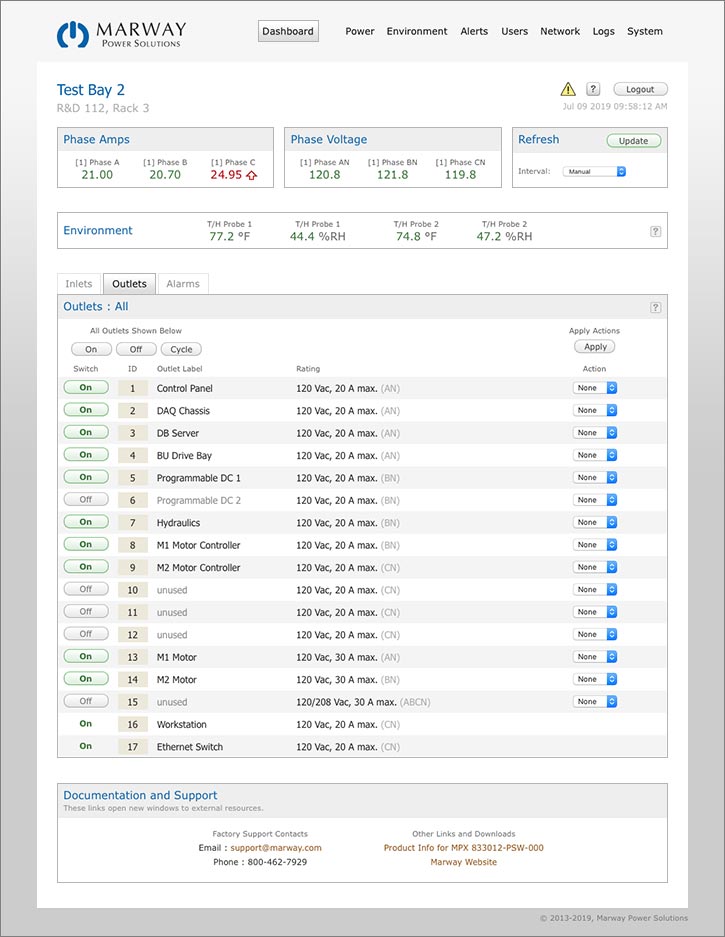

Monitoring ↑

Power monitoring with digital displays and status indicators provides confidence that downstream equipment is getting what it needs. This might include tracking power quality, available capacity, and simple on/off status of circuits or outlets. Whether for local visibility or remote connectivity to factory automation, Marway can consolidate power monitoring needs into the PDU to optimize power management space and cost.

Outlets ↑

An outlet is an outlet. Yes? Well, not really. Ac, dc, high voltage, low voltage, commercial, industrial, military, aerospace all have unique requirements. There are numerous standard outlet forms from common appliance outlets we see in homes and offices to larger capacity forms with twist locking safety features to specialized pin and sleeve connectors suitable for high vibration environments. It’s even common to have simple lug nuts or screw terminals. Chances are if it’s ever been used to send a power signal, Marway has used it.

Enclosures ↑

Other than width and height increments, there’s little that is “standard” about a rackmount enclosure. You’ve seen photos of several rackmount PDUs on this web site—and seen that they can differ quite a lot. Even with all that customization, a rackmount enclosure is not always the best solution. We create most of our own enclosures, so we’re able to create custom shapes and sizes from the rather small to the rather large.

Add Marway’s RCM Software ↑

The Optima RCM (remote control and monitoring) software adds remote outlet switching and inlet power monitoring over Ethernet® via HTTP/S, SNMP, Telnet, and SSH. Below are some highlights of the RCM software capabilities:

- Remote control of outlets (manual and scripted)

- Inlet current and voltage monitoring

- Event alerts for startup, user login, outlet state change, EPO, power setpoint excursion, and configuration changes (via SNMP, email, SMS)

- HTTP and HTTPS for web browser access

- Telnet and SSH for command line access

- SNMP monitoring, control, and alerts

- RESTful API over HTTP/S to script outlet automation

- Multiple users with independent login credentials

- On-board activity log (SNTP time stamps)

AC Power Range ↑

General purpose industrial PDUs start in the 15 to 30 A range. From there, medium-capacity products between 30 and 100 A are common for industrial and defense applications. Specialized high-capacities up to 400 A are still a regular project for us. Likewise, we work with a wide voltage range from 24 Vac to 480 Vac. While these are typical capacities and voltages, Marway can incorporate virtually any single phase, split-phase, or three-phase power standard needed.

AC-AC Conversion ↑

It’s quite common to have only one power utility form available, but need other forms for distribution. For example, converting 208 Vac to 115 Vac, or vice versa. Also, single-phase power can be derived from a three-phase inlet (which does not require a transformer).

AC-DC Conversion ↑

Using power supplies, we can create dc voltage from an ac input source. Dc can be used for internal controls, and for power distribution as well. In fact, we can even make more than one dc voltage to suit multiple needs from the same PDU.

EMI Protection ↑

Electromagnetic interference can degrade the quality of an ac signal. Shielding, EMI filters, and even transformers help eliminate these problems. Component selection can be for broad, general purpose results, or to mitigate specific identified influences.

Surge Protection ↑

Spikes and surges can be injected or induced into power systems from lightning and switching of high power devices. Integrated surge protection devices can absorb or divert high voltages to protect downstream equipment.

NEMA Outlets ↑

NEMA defines US standards for many electrical power connectors. So, of course, Marway offers any NEMA standard outlet connector which may be needed. Common wall outlets are known as 5-15R and are rated for 15 A and 125 V. These have straight blades, and are quite common in PDUs to provide power to commercial and industrial equipment. Since these connectors are relatively small, they can be tightly packed for high density needs. Other versions allow for higher current, higher voltage, and three-phase power.

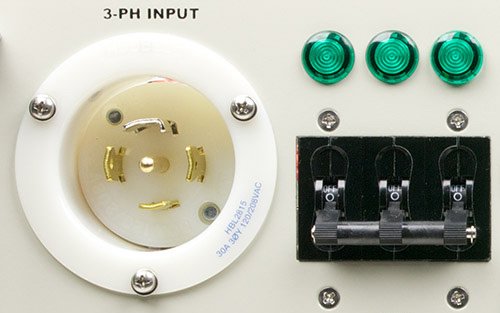

NEMA Twist Locks ↑

Twist-lock style connectors require the connector be pushed in, then twisted to engage a mechanical catch. This helps prevent the connector from being accidentally bumped loose. Compared to straight blade connectors, twist-lock connectors also reduce the risk of a loose connector exposing parts of the power-carrying blades. They’re great for improving both connection reliability and safety.

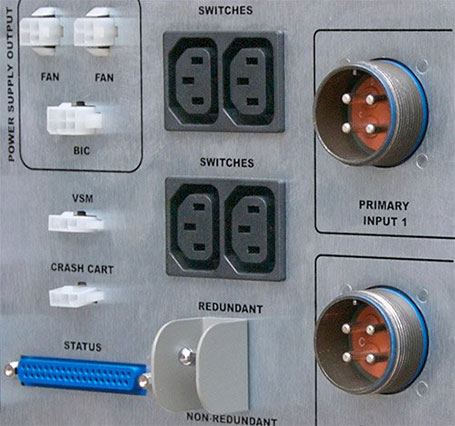

IEC Outlets ↑

IEC is a European standards body similar to NEMA. However, a few IEC connectors are commonly used even in the US for computers and similar equipment. While the US uses 115 Vac for most home and business wiring, much of Europe uses 230 Vac. Since most mass-market electronic equipment is designed to run at either 115 or 230 Vac, the IEC connectors are used. Just as with NEMA connectors, Marway can offer IEC connectors of any type on a PDU.

Circular/MIL Connectors ↑

Circular/MIL connectors are for environments exposed to moisture, sand, vibration and other hazards. They use a threaded barrel interconnect between mating parts, and so provide an even more secure connection than twist locks. These connectors are common in defense, aerospace, and rugged industrial applications.

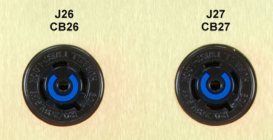

Outlet Switching ↑

Local switching of circuits or outlets can be done with circuit breakers, or any number of panel switch styles. Additionally, remote switching methods can be incorporated to allow remotely located panels to enable/disable specific circuits or individual outlets. Marway has a standard remote EPO/on/off system designed for it’s Commander EPO panels.

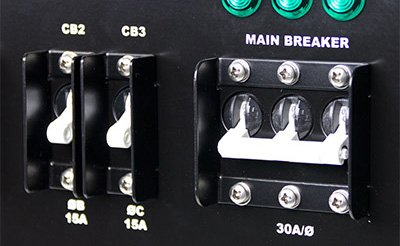

Circuit Protection ↑

Breakers can be used to protect the PDU as a whole, individual power branches, or even each individual outlet. There are a variety of technologies (thermal, hydraulic magnetic, etc.), a variety of form factors, different certifications (UL 1077, UL 489), as well as other characteristics. You can count on Marway to select the best fit for the application.

Signal Connectors ↑

Given Marway’s specialization in custom products, in addition to the connector types we’ve mentioned above, we’re able to utilize any connector for control and power signals which your environment requires.

Panel Meters ↑

Marway can integrate panel meters for voltage, current, and power quality monitoring using either discrete LED displays or off-the-shelf industrial meters. If remote monitoring or factory automation integration is required, there are several meters which offer connectivity using a variety of standard industrial protocols.

Connectivity ↑

In addition to discrete-signal-based outlet switching, Marway offers an Ethernet solution for remote switching. An on-board embedded operating system provides Telnet, SSH, Web, and RESTful API interfaces for manual and automated control of outlet state. Read more about the technology on our Connectivity page.