Industrial Power Distribution Units

Meeting Industrial Power Challenges

Industrial PDUs differ from commodity PDUs in being more robust, in using technologies to clean up noisy facility power sources, and in the ability to include specialized controls and connections needed in industrial environments. In many cases, industrial PDUs are also designed to serve in harsh physical environments.

Marway has been meeting the needs for industrial PDUs in manufacturing, labs, mobile platforms, service bays, as support for research and product development, and more for over 30 years.

What to look for in an industrial PDU ↑

- Protects downstream equipment from noisy facility power using EMI filters, surge suppressors, and other techniques.

- Saves space by integrating conditioning and conversion needs instead of housing them as external boxes.

- Improves integration by providing the exact connectivity and controls needed for site-specific equipment.

- Complies with general and industry-specific standards for electrical power handling equipment.

- Meets harsh environmental needs.

What to look for in a PDU supplier ↑

- Takes the time to understand the application, explore needs, and consider design options.

- Optimizes the selection of application-specific components for capacity matching, packaging efficiency, and cost.

- Designs and manufactures enclosures to meet unique needs for installation, cable routing, and other integration details.

- Manages the entire process of standards testing and certification, when required, prior to delivery.

Your choice of custom or standard ↑

- Marway specializes in application-specific PDUs.

- Rackmount chassis from 0U to 24U, to rack sized.

- Custom enclosures for non-rack applications.

- Ac, dc, up to 600 volts, 400 amps.

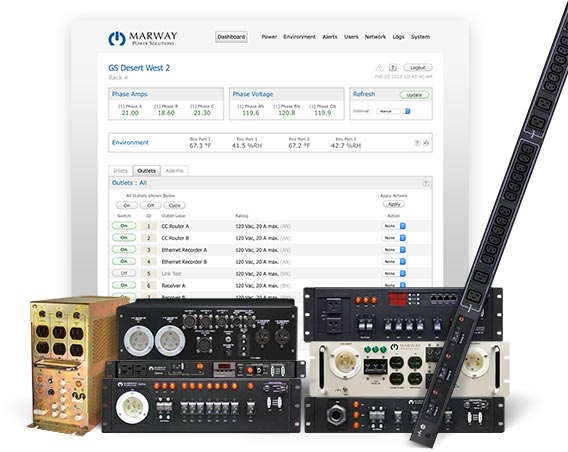

- We also have nearly 300 standard basic and smart PDUs.

- 1-phase, 3-phase, 15-, 20-, and 30-amp models.

- 1U, 2U, 3U, and vertical 0U configurations.

Integrated conditioning, conversion, and control ↑

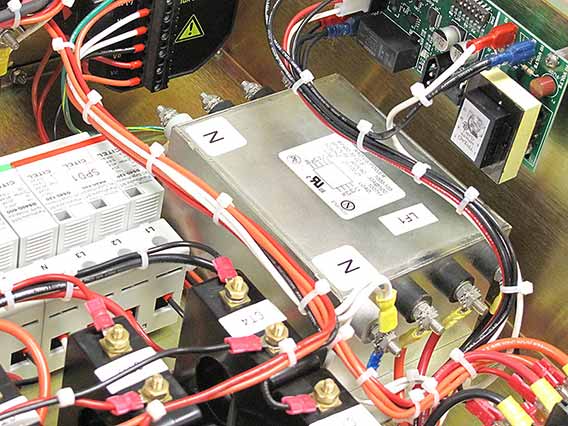

- Reduce EMI using filters and other techniques.

- Mitigate voltage spikes/transients using surge suppression.

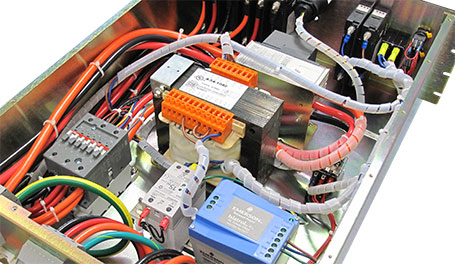

- Integrate ac and dc sources into a single system.

- Use conversions of ac-ac, ac-dc, dc-dc, and dc-ac to create needed power forms.

- Optimize local and remote power monitoring and switching.

- Improve safety with EPO and interlock circuit integration.

Networked or non-networked controls ↑

- Non-networked PDUs still offer some remote switching through discrete signals from remote panels.

- Networked PDUs offer remote outlet switching and power monitoring over HTTP/S, SSH, Telnet, and SNMP.

- PDU software automates alerts for several operational events via SNMP, email, SMS.

- Automated outlet control and periodic data collection is scriptable through Telnet, SSH, SNMP, or RESTful API.

Standards and compliance management ↑

- Certified ISO 9001 (with AS9100).

- Products designed and manufactured to UL/IEC 62368-1 and 61010-1 (others when required).

- UL and CE certification (others when required).

- Environment and reliability testing when required.

What is an Industrial PDU? ↑

An industrial PDU is an electrical power distribution unit designed to meet the needs for stable power and unique integration of industrial environments. They typically include features to clean up signal problems seen with noisy power in industrial facilities, and include control and safety features not found in commodity PDUs. Being specialized for industrial applications, these PDUs also tend to have a wider variety of connection and power options compared to commercial products. As with any industrial equipment, heat, cold, rain, dust, and vibration tolerance may be required as well.

Key Capabilities of Industrial PDUs

- Reduces or eliminates conducted and inducted electro-magnetic interference (EMI) from nearby electrical equipment.

- Protects against voltage spikes created by high-powered equipment on the same lines, and lightening strikes near outside transmission lines.

- Integrates remote interlocks to cut power to outlets to meet industrial safety requirements.

- Creates multiple power forms from a single facility power source such as higher or lower voltages, or even dc power from ac power and vice versa.

- Adopts the use of specialized connectors and outlets to interface to existing customer equipment, safety systems, and more.

- Handles harsh environment conditions such as dust, rain, ice, heat, and vibration.

Cleaning Up Noisy Power ↑

Noisy facility power signals occur in factories, test labs, service bays, and other industrial environments due to the varying loads of nearby high-powered equipment. Like sudden water pressure surges cause pipes to rattle, sudden surges of “pressure” and “flow” (voltage and current) in electrical lines cause signal abnormalities. Where a weak fitting along a pipe might leak, a vulnerable component in an electronic system may fail.

Most commodity PDUs are designed for office-like environments where there is little influence on power signals from nearby equipment. At most, these PDUs may have some surge protection since those devices are relatively low cost and small.

Industrial PDUs integrate surge suppression, EMI filters, isolation transformers, and other tools to mitigate the severity of noisy facility power signals coming from many different sources. Selecting these components requires an understanding of the types of noise which are expected in the environment, and matching various attributes of the components to the power form being conditioned.

Creating Needed Power Forms ↑

Many industrial environments need a mixture of different power forms. A power form is the combination of specifications for voltage type, voltage rating, and current rating. For example, 120 Vac, 15 amps vs. 80 Vdc 60 amps are two different power forms.

A building’s facility power will usually be wired for two or three forms, but they won’t all be routed to all work areas. In industrial environments, this is most typically three-phase ac power for some areas in addition to common 120 volt wall outlets. In various manufacturing or laboratory stations, there may be a need for more types of power. Ac may be needed in multiple three-phase and single-phase forms. Different voltages may be needed to serve the larger and smaller pieces of equipment. Even dc power is often needed in the same work spaces as ac power.

Industrial PDUs can integrate transformers, power supplies, and power converters to create multiple power forms from a single facility wall source. This can simplify installation, and provide better control options compared to having multiple power services wired into facility walls.

Meeting Exact Control and Connection Needs ↑

Industrial PDUs offer a wider range of circuit designs, control features, power monitoring, and even remote management capabilities. Most commodity power distribution products have a single circuit serving all outlets with perhaps an on/off switch or breaker. Industrial environments often require more control over multiple individual circuits. For many applications, digital power displays are important. Indicators for the status of specific circuits and interlocks are simple additions, but unique to each application. Adapting to these unique switching, display, and control needs, is a key capability in an industrial PDU.

Another area of important flexibility for an industrial PDU is that of cable connectors. Many people are aware of only the common wall sockets in offices and homes. In the industrial realm, there are hundreds of unique connectors. There are standardized ac power connectors, but even then there are dozens of types depending on voltage, current, safety features like locking, resistance to water, vibration, and more. Even more than power connectors, control signal connectors are even more varied. Integration to external interlocks, sensors, and more require that a PDU have the flexibility to incorporate what a facility needs.

Standard industrial PDUs, like Marway’s 5 and 8 Series, can be designed with very common connections and controls, but ultimately, many industrial applications use a custom design.

Handling Harsh Environments ↑

A consideration for some industrial power distribution applications is the environment the PDU will be used in. Industrial often means outside. Enclosures, connectors, and controls may need to handle dust, rain, and even the build up of ice. Even indoor systems may be subjected to significant dust and/or the potential for water splashing.

Vibration and shock may also be a consideration. PDUs mounted to mobile platforms need to handle vibrations and possible jarrings experienced on the road, in the air, or even at sea.

Whether outdoors or indoors, temperature can also be an extreme environment factor. To handle cold environments, specialized components, or even internal heating, may be necessary. Depending on the use of electronic controls in the PDU, cooling by convection venting or fans may also be an issue for very warm environments.

Since most pre-designed, standard PDUs are going to be designed for general purpose applications, they’re not likely to meet many harsh environment needs. Most harsh environment applications tend to be unique in their power needs anyway, so custom designs are often used. Marway specializes in custom PDU applications, and is experienced with a number of the skills and standards used to handle harsh environments.