Optima™ Custom PDUs

Product SelectorA Partnership Perspective ↑

Marway’s core business is application-specific PDUs designed to meet unique requirements. Our customers often discover we can do more than they expected to simplify the development, compliance testing, purchasing, and manufacturing of their power infrastructure needs. So, when your project’s power needs are more than standard, consider the advantages of having Marway create a custom PDU solution.

- We provide cost-competitive collaborative design, turn-key manufacturing, and compliance certification management in parallel to your in-house team.

- Often, we provide shorter turn-around times than in-house teams, because we’ve already solved similar challenges, done component research, and have many of them in stock.

- Our power engineering expertise assures properly matched components for efficiency, signal quality, and reliability.

- Our experience with safety- and compliance-qualified designs and components helps to avoid late-stage redesigns with in-house projects.

- And, of course, you end up with a power management solution which perfectly suits your project’s needs.

Custom PDU Development ↑

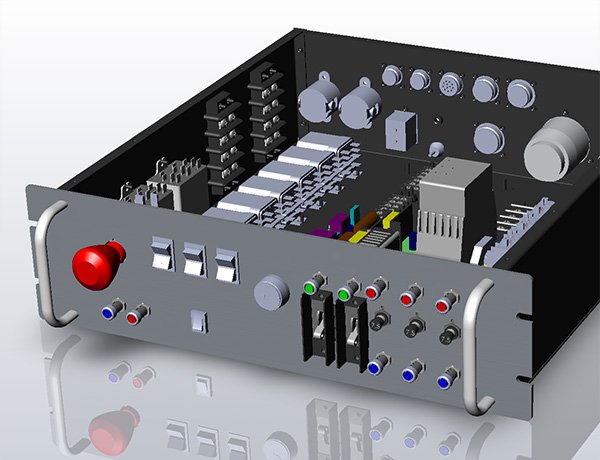

A new PDU design from Marway begins with a discussion about the purpose of the PDU, and the environment in which it will function. To help identify key technology needs, we’ve organized common power management capabilities into the groups of conversion, conditioning, control, and monitoring. In each of these areas, circuit by circuit, we help identify core requirements along with any technical or commercial constraints.

Next, we consider the physical environment needs from vibration and temperature tolerance to details of installation and operator ergonomics. When specific standards compliance must be proven, Marway can manage the test and certification process.

By involving both your team and Marway’s in a collaborative approach, a more complete understanding of the application, environment, and purpose of the PDU allows everyone to better interpret the project’s needs, and leverage experience towards a more successful design.

Select Best-Suited Options ↑

Having identified key technology requirements and constraints, the design process will move into component preferences. You may prefer specific components based on experience, existing support stock, or other reasons. Likewise, Marway may suggest specific components based on its experience with specific applications. Next, we consider the operator panel for logical layout. Front, back, left, right—placement may matter based on nearby equipment, and design uniformity with other equipment may also be desired.

Between technologies, components, panel layouts, and more, there are a lot of options to consider. For many cases, Marway handles defining all these options. With others, there’s a lot of hands-on process with the customer. Either way, considering these options helps us to better balance performance, cost, space, and other design factors which create a successful design.

Optimize the Packaging ↑

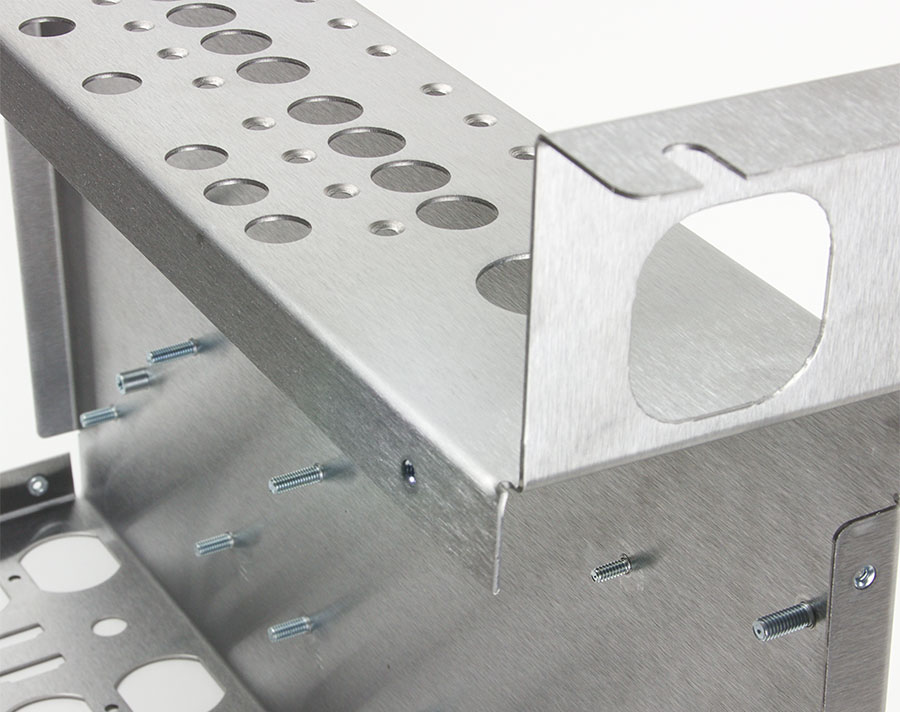

When creating an integrated solution, we address the unique needs of that application. We optimize the selection of components for performance, capacity, space, accessibility, value, and other design parameters. This optimization extends even to the enclosure. By having in-house chassis fabrication, we’re not boxed in by standardized sizes and panels. Even “standard” rackmount enclosures don’t have to be identical—we can always adjust depth and recessed mounting. For many OEM/VAR applications, enclosures will be in rather unique shapes and sizes.

Regardless of form factor, we create enclosures so they complement all other design decisions to result in better panel layouts, labeling, operator conveniences, installation advantages, and more.

Collaborative Solutions ↑

Designs can be complex things when satisfying numerous and sometimes competing objectives. Whether for rack-sized power centers, or specialized high-volume OEM power boxes, the best designs often come from collaboration. Marway’s engineers are experienced at working within multi-functional design teams, and managing multi-stake-holder projects.

Preliminary concepts, mockups, and even functional prototypes can play a key role in ensuring that complex or high-volume designs are well thought out before committing to final production. Marway is able to offer any or all of these services on a project.